PAC-CLAD Flush Panels are designed for wall, fascia and soffit applications where a flush or flat appearance is desired. A rounded interlock leg and concealed fastening system act to improve the flush appearance while providing additional strength. Panels are factory-formed to length to minimize field cutting (minimum panel length is 4 feet).

PAC-CLAD Flush Panels are available

in on-center dimensions designed to complement our roofing panel product line.

Flush Panels are available in two configurations:

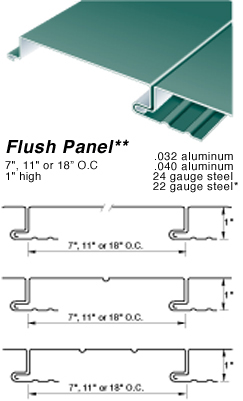

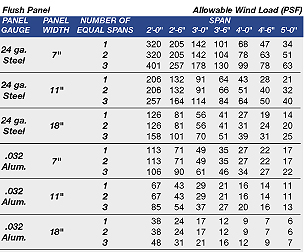

•Flush Panel

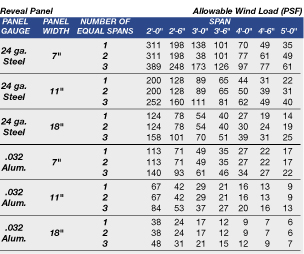

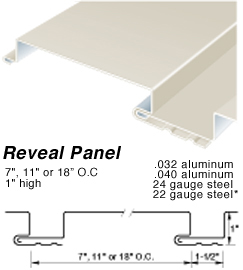

•Reveal Panel

Flush Panels

Uses: PAC-Flush Panels are intended for use as vertical wall panels, fascia and soffit applications. Flush Panels are not intended for use in roofing or mansard applications.

Materials

a) 24 ga. G-90 hot-dipped galvanized steel b) 22 ga. G-90 hot-dipped galvanized steel c) .032 3105-H14 aluminum or equal d) .040 3105-H14 aluminum or equal

Stiffening Beads

The Flush Panel and Reveal Panel are available with optional stiffening beads. Stiffening beads are recommended for longer panel lengths. One, two or three beads are available.

Installation

PAC-CLAD Flush Panels shall be installed over a solid underlayment or over framing sections as manufactured by Petersen Aluminum Corporation. When used in a windscreen application, panels must be fastened (stitched) through side joints. Consult a local architect/engineer for requirements of local codes and conditions.

Corrective Leveling

Petersen Flush Panels are formed on precision roll-forming equipment that includes in-line Herr-Voss corrective levelers. Corrective leveling works to remove typical metal conditions including coil set, crowning and edge wave. In-line leveling capabilities allow us to work with source material that is "still-water" flat. The result is a panel that exhibits superior flatness. Corrective leveling is available at no extra charge. This panel is not available vented.

| Product Features | |

| •Corrective

leveled for superior flatness •Available with up to 3 stiffener beads •Rounded interlock leg provides improved flush fit •.040 aluminum panel |

|

| Material | |

| |

•30

standard colors (steel) •20 standard colors (aluminum) •11 standard colors (22 gauge steel) •20 year non-prorated finish warranty • Galvalume Plus available |

| |

A complete ManuSpec¿ specification is available on request from Petersen Aluminum Corporation

|

Architect: HKS Architects

General Contractor: Faulkner Construction

Roofing Contractor: Top Concepts

Color: Zinc Metallic

Profile: Flush Panel & Tite-Loc Coping

*Limited color availability

**18" O.C. available in limited applications. Consult factory for details.

3105-H-14 alloy for aluminum panels